|

1. Introduction It is well known that repeated unsteady motions of walls of a container filled with a highly viscous fluid or unsteady motions of solid bodies immersed in the fluid can produce a chaotic mixing in the fluid, which is called "Lagrangian turbulence" (Ottino, 1989a,b). It can be visualized by adding some dyes with the same viscosity beforehand. The main interest in this phenomenon has been the mechanism of chaotic behavior as a result of accumulation of dye displacements. In fact, resultant dye patterns are similar to the Poincare maps characteristic of chaotic behavior of dynamical systems. On the other hand, this phenomenon has been attracting fluid-dynamists because of the beauty of resulting patterns. This fact may suggest that this phenomenon can be applied as a new method of creating artworks. The term "rheo" in the title means a flow, and "rheo-art" should mean an art produced by application of the fluid dynamics. Since there are a lot of flow patterns in the nature, there should be also many kinds of rheo-art. However, in this paper we confine ourselves to the viscous mixing noted above, simply because it is relatively easy to simulate this flow.

The present author has recently made an attempt to apply 2D (two-dimensional) chaotic

mixing to produce attractive patterns by numerical method (Takaki

& Tomioka, 1997). In thepresent paper this attempt is applied

to other 2D configurations of cylinders and also extended to a 3D configuration.

Furthermore, it is tried to make up solid models form the computed results

with a help of a sculpture artist, Mr. Y. Nakatsugawa. The purpose

of this paper is to present results of these studies, and to make a fundamental

discussion on similarities and differences between art and science.

2. Method of Computation

The 2D

chaotic mixing is produced by a method similar to that first introduced

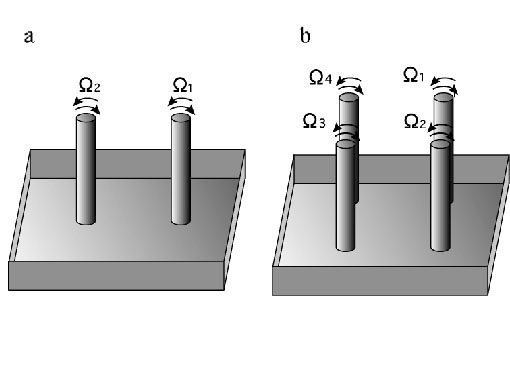

by Aref (1984). In his computation two circular cylinders were set

vertically in a container filled with a viscous fluid (see Fig. 1a).

They are rotated around their axes very slowly by certain angles in turn,

so that only one cylinder is rotated while the oher is at rest. The

fluid around a rotating cylinder moves according to the theory of

slow flows, i.e. the velocity induced by the rotation is inversely

proportional to the distance from the cylinder axis.

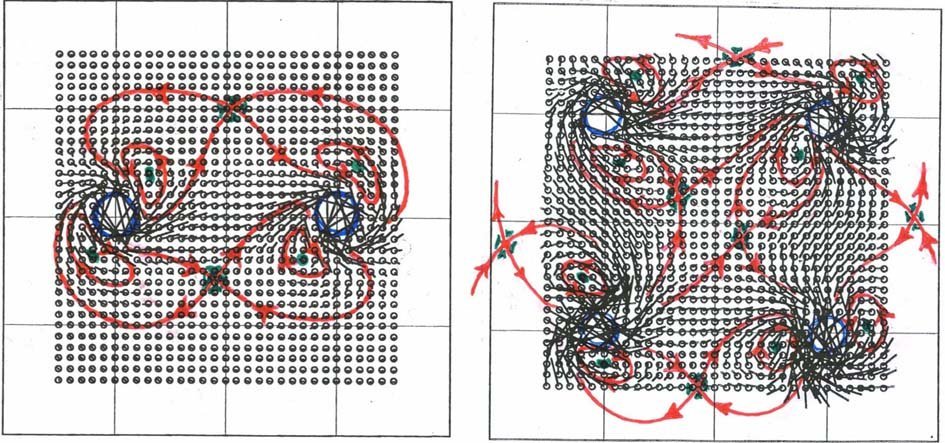

In the present paper cases with two and four equal cylinders are tried (see Figs.

1a and 1b). Rotation angles of cylinders and the order of their motions

can be chosen arbitrarily. But, a common rotation angle is chosen

and the sense of rotation of each cylinder and the order of motions are

left arbitrary.

When a flow field is produced by rotation of one cylinder, the flow is modified

by existence of other rest cylinders because the fluid should go round

these objects. However, in this study their effects are neglected

in order to simplify the computation of fluid motion. It is allowed

when mutual distances between cylinders are much larger than

their diameter.

In a typical case of two cylinders, which are denoted with surfices 1 and 2,

respectively (Fig. 1a), they are rotated by angles in an order,

This expression show that the

following four processes constitute one step of operation: cylinder 1 is

rotated clockwise by 180°, cylinder 2 clockwise by 180°,

cylinder 1 anti-clockwise by 180°, then cylinder 2 anti-clockwise by 180°.

Note that the clockwise rotation is denoted by a positive angle.

This operation is repeated by arbitrary number of steps so long as computing

time is available.

In the case with four cylinders a similar expression of processes is employed

(Fig. 1b). In this case one step of processes is expressed as

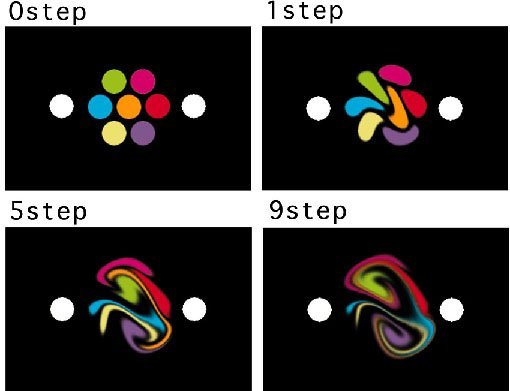

At the beginning several spots of dyes with many colors are placed on the fluid

surface, where the viscosity of the dye is assumed equal to that of the

fluid, so that the dyes move according to the same rule as for the fluid.

Number, shapes, sizes and positions of initial dye spots vcan be given

also arbitrarily. But, by try-and-error one may find that most interesting

patterns will be obtained when several spots are placed within the central

region, so that initial spots are surrounded by cylinders. In the

first case with two cylinders seven dye spots are placed in hexagonal configuration

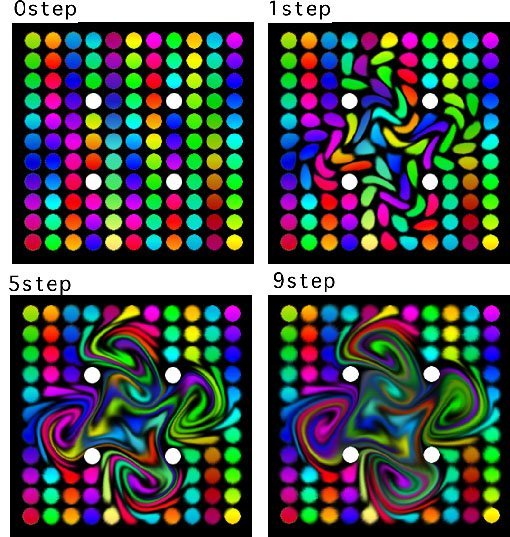

(Fig. 3). In the case of four cylinders a lot of spots are

placed in square grid configuration (Fig. 4).

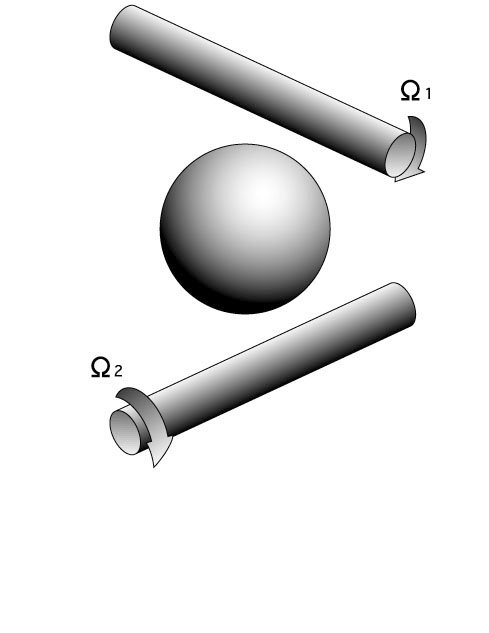

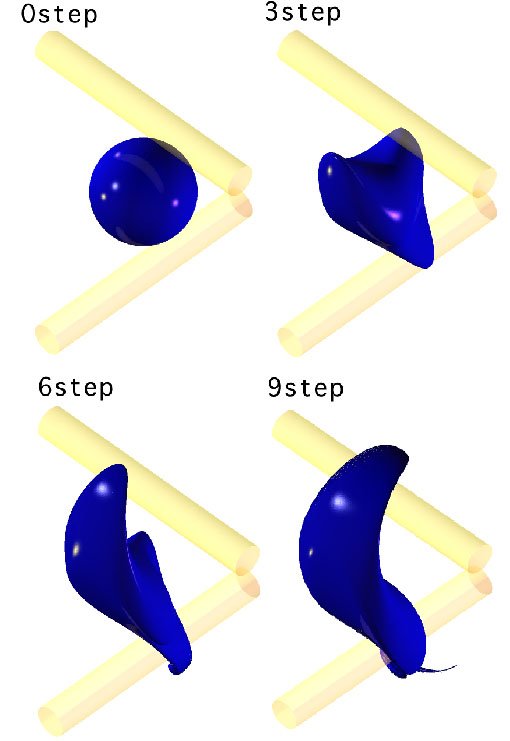

Similar processes are made in the case of 3D viscous mixing. In this study

two equal cylinders are set perpendicularly in a deep container of a viscous

fluid with their axes apart, and one spherical dye is placed between the

two cylinders as an initial condition. Each cylinder is rotated one

after another by 180° always in the same direction, i.e.

The fluid is assumed to

go round the rotating cylinder in a plane perpendicular to the cylinder

axis, where the effect of the other cylinder is neglected as mentioned

above.

It is worth noting that it must be also interesting to undertake real experiments to produce mixing patterns, although there may arise some difficulties, for example in suppressing dye diffusion and initial fluctuation of dye inputs. In addition many other cases with various cylinder arrangements (or with other solid objects) and initial dye patterns could be tried to see whether they lead to attractive patterns. Readers are suggested to try themselves. At least the 2D mixing is easy and anyone can begin immediately, if he(she) has a personal computer.

3. Results of 2D cases

Fig. 3 shows an initial dye pattern and its deformations after several steps in

the case of two cylinders due to the four-process operation (Eq. (1)).

Readers might agree that delicate and beautiful patterns are obtained.

The resulting patterns have two complicated swirling centers, each of which

by close observation is seen to be a mixture of rotations of opposite senses.

The whole pattern does not have a symmetry inspite of the symmetrical configuration

of cylinders. It is owing without doubt to the asymmetry of operation,

i.e.

the right cylinder is rotated first. This coexistence of large scale

order and asymmetry seems to give an attractiveness to these patterns.

The displacement

vector field corresponding to one step of four-process operation is shown

in Fig. 5 (left). In this figure the angle of rotation is increased

to 360°

so that fluid dispalenments are seen more clearly.

Some trajecroties are also drawn on the map. The complicated swirling

centers are located near both to the hyperbolic point (saddle point) and

the elliptic point (vortex) in the map. It is in accordance with

the common fact established in the chaos dynamics. It is interesting

to point out that the swirling centers are nearer to the hyperbolic points

(not the elliptic points) inspite of their swirling nature!

Resulting patterns in the four-cylinder case are shown in Fig. 4. They have

4-fold symmetries corresponding to the square configuration of cylinders,

but the symmetry is broken owing to the asymmetry of operation, as in the

two-cylinder case. The fluid displacement map, shown in Fig. 5 (right),

is much complicated, but one can recognize six hyperbolic points and eight

elliptic points. The two hyperbolic centers within the cylinder square

seem to contribute much in formation of highly chaotic mixture at the center.

The hyperbilic points located out of the cylinder square are located near

to the outer swirling centers as in the two-cylinder case.

4. Results of 3D cases

Some of dye patterns up to the 9th step in the 3D case are shown in Fig. 6.

The 9th pattern is displayed once more in Fig. 6(below) by the use of a

software of ray-tracing. As is seen from these patterns, the

dye continues to be wound to the two cylinders and aquires a long thin

tail at one end. Appearance of a thin tail is observed also in 2D

cases and not so surprising, although it is more complicated in 3D cases.

As is mentioned in Sec.1, this 3D simulation can

be applied to art creation, i.e.

a sculpture. A shape constructed from the 3D simulation is called

a "scientific model", because it is also a scientific result. A scientific

model was constructed to a solid model fairly faithfully with a help of

a sculpture artist, Y. Nakatsugawa. A more precise discussion will

be given on the meaning of "scientific" in the next section in terms of

"repeatability".

Along with this scientific model the present author asked the artist to create

a solid model with a new shape according to his inspiration from this model,

which is called an "artificial model" (see Fig. 7). The term "artificial"

means that the model reflects the artist's desire and concept but the repeatability

is not expected, as is usual in hand works.

There are some clear differences between these two models. First, the artificial

model lacks the thin tail. Second, the surface of the artificial

model has a spherically concave part, which lacks in the scientific model.

Third, the thickness distributions are different (not apparent from this

picture), so that it tends to change monotonically in the scientific model,

while the artificial model has wavy distribution. In other words

the scientific model has a thickness distribution like that of a knife,

while the shape of the artificial model is more biological. These

characteristics of the artificial model may reflect the artist's ideas. When

the present author showed these models to participants of a conference

(Takaki & Tomioka, 1997), most of them preferred the artificial model

to the scientific model, except one who is an engineer.

Fig. 7

Solid models produced by Y. Nakatsugawa. left: faithful

copy of the 9th step

(scientific model), right: a shape created by Y. Nakatsugawa (artificial

model).

5. Discussions

Results shown above would suggest that the simulation of chaotic mixing of a viscous

fluid can provide a new method of art production. Especially, the

2D simulation is made by the use of a conventional softwares and

is open to anyone who can use a personal computer. On the other hand,

production of scuptures from computer simulation is still difficult at

present for general people, because they must be engaged in computer programming

and must have partners to help them in making solid models from computer

data.

As for the solid model production from computed data there is a possibility to

utilize a facility for photo-solidifying reaction, so that computed surface

shapes are automatically reproduced to plastic models. The present

author is considering to try this method in near future.

This author has been using the term "art" too easily without discussing its

meaning. Here, some discussions are given on the common features

and differences of science and art on the basis of the author's experiences

during activity of this work. This problem can be treated from variety

of aspects and discusser's standpoints, but the present author would like

to put a stress on the following points.

Science and art are similar to each other in:

Their objects are to create

new knowledges (new forms), and originalities are important.

Their results should be

presented to public and new human communications are triggered

therewith.

Utilities of results are

expected by society, but scientists (artists) prefer to be free from the

utilies.

On the other hand, science and art are different in the

processes of creations as listed below:

In science the repeatability is important,

i.e. if the same conditions are given, the same results

must be obtained. Therefore, especially in experimental works,

artificial control of phenomena during an experimental run is avoided.

In art, on the other hand, the human sensitivity to the artwork is important

and repeatability is neglected, so that artificial control to improve the

resullts is continuously made during production and no equivalent pieces

of works are producued even by the same artist.

The mental processes occurring

in scientists and artists are just opposite to each other.

The science is an activity to extract natural laws from real phenomena,

which is to convert form to concept. On the other hand,

the art is to produce real forms out of artist's imaginations, which is

to convert concept to form.

These two differences look very much critical, hence science and art have been supposed

to belong to different categories of human activities. However, in

spite of these differences they have a close relation as ointed out above.

Now, as for the rheo-art proposed here, it is considered to belong to the category

of science, because the process of production is that of science.

In fact, initial conditions are given and algorithms of dye deformations

are determined first, then the later processes proceed automatically without

any artificial manipulation. There is still a room for the human

sensitivity to play a role, by choosing better results from scientific

results and adjusting initial conditions or parameters. This

way of creation is called here "rheo-art".

However, we need an appropriate facility in order to display results of rheo-art.

In the present work we have no problem with the 2D cases, because convetional

color printers are enough for that purpose. On the other hand, displays

of 3D works are not straight forward. In fact the present author

needed a cooperation with a scuplture artist to make solid objects.

Is the light-solodification technique becomes more popular, this problem

will be solved. The present author is considering to try this way

in future.

It is hoped that the rheo-art will become possible by much easier method so that

many people can use it. A true art should be based on simple technologies;

Picasso used the same tools which we are using now.

Acknowledgements

The present author would like to express his cordial thanks to Mr. S. Tomioka for his

long term helps in computer simulations and to Mr. F. Nakatsugawa for his

kind efforts to make up solid objects from computed data. The present

work would not have been completed without their helps.

References

Aref, H., 1984, Stirring by chaotic advection, J. Fluid Mech. 143, 1-21.

Ottino, J.M., 1989a, The Kinematics of Mixing, Cambridge Univ. Press.

Ottino, J.M., 1989b, The mixing of fluids, Scientific American, January, 40-49.

Takaki, R., 1994, Proposal of a new kind of art "Rheo-art",

FORMA, 9,

203-208.

Takaki, R. and Tomioka, S., 1997, Mixing of viscous fluid

and its application to art,

Abstracts of 2nd Int. Conf. on Flow Interaction, Berlin, 1997,

3-5.

|